OPTIMIZE YOUR POULTRY FARM OPERATIONS WITH ADVANCED POULTRY FARM CONTROLLERS

Maintaining a healthy and productive environment in a broiler farm requires more than just good management—it demands precision, automation, and adaptability. This is where poultry farm control systems come into play, offering a comprehensive solution to manage every critical aspect of your poultry house environment. At the forefront of this innovation is the Linotouch series of environment controllers, designed to transform broiler farm management through intelligent sensor integration and user-friendly technology.

Precision Control for Peak Performance

Broiler chickens are extremely sensitive to changes in environmental conditions. Variations in temperature, humidity, air quality, and ventilation can have a direct impact on flock health, feed conversion ratios, and mortality rates. Poultry farm control systems like Linotouch eliminate guesswork by providing real-time monitoring and automated control over all essential environmental variables.

These advanced systems utilize a network of high-precision sensors to measure:

Temperature – Maintains optimal thermal comfort zones across the poultry house.

Humidity – Regulates moisture levels to prevent respiratory issues and litter degradation.

Static Pressure – Ensures efficient air exchange for proper ventilation without energy loss.

Ammonia Levels – Detects harmful gas concentrations and activates exhaust systems to prevent toxic buildup.

Carbon Dioxide (CO₂) – Controls ventilation to maintain breathable air and reduce stress on birds.

By combining all these parameters, Linotouch environment controllers ensure that your flock always lives in a clean, safe, and productive atmosphere.

With seamless integration, you can:

Monitor feed consumption trends in relation to temperature changes

Analyze flock behavior through real-time environment correlations

Automate responses to sensor alerts without manual intervention

Ensure biosecurity through alert-driven ventilation and climate strategies

This level of integration results in better planning, fewer losses, and more consistent production cycles.

A Complete Farm Management Solution

More than just a climate controller, Linotouch is part of a larger farm management ecosystem. When integrated with other poultry automation technologies—like feeding systems, lighting, weighing scales, and water flow monitors—these poultry farm control systems become the nerve center of your operation.

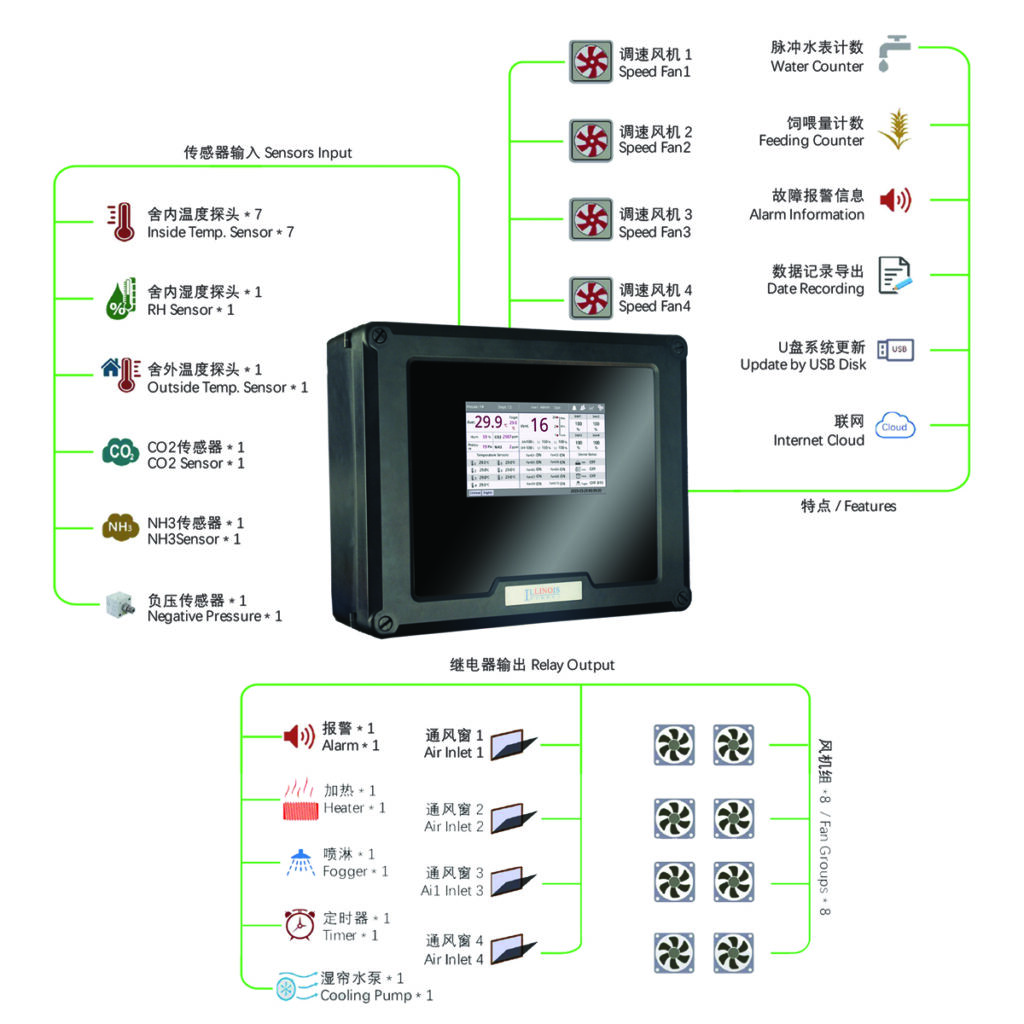

LINOTOUCH SE+

Input

7 temperature sensors

1 Humidity sensor

1 Carbon dioxide sensor

1 Ammonia sensor

1 Negative pressure sensor

Output

Upto 10 fan groups

Upto 4 speed fans

Upto 4 air inlet control zones

1 heater

1 misting/fogging

1 cooling pump

1 timer

1 Alarm

Features

Water counter

Feed counter

Data recording

Alarm recording

Internet remote access

Smarter Control at Your Fingertips

What sets the Linotouch controller apart from conventional systems is its intuitive touchscreen interface and robust automation features. It’s built to support farmers with easy-to-use, visual tools that allow full oversight and customization.

Whether you’re on-site or managing remotely, the system offers:

Customizable ventilation and heating schedules

Alarms and real-time alerts via SMS or app notifications

Data logging for performance analysis and auditing

Remote access through cloud-based interfaces

Integration with lighting, feed, and water control systems

For the modern farm manager, Linotouch turns environmental control into an effortless and centralized process.

Poultry farms operate on tight growth cycles and narrow margins. Every day of optimal performance contributes significantly to overall profitability. Linotouch’s environment controllers are fine-tuned to cater to the high-performance demands of poultry houses, delivering consistent environmental quality from day-old chicks to harvest time.

Their rugged build and weather-resistant enclosures make them suitable for installation in harsh farm conditions. The controllers can be easily upgraded or extended with additional modules, giving farms of all sizes a scalable solution that grows with their needs.

Designed for Poultry Specific Needs

LINOTOUCH PRO+

Input

10 temperature sensors

2 Humidity sensor

1 Carbon dioxide sensor

1 Ammonia sensor

1 Negative pressure sensor

Output

Upto 56 relay outputs

Upto 6 heating control zones

Upto 12 air inlet control zones

Upto 48 fan groups

Upto 4 cooling zones

Features

Water counter

Feed counter

Data recording

Alarm recording

Internet remote access

Efficiency and savings

In today’s competitive poultry industry, maximizing efficiency and flock health is not optional—it’s essential. Investing in a reliable and intelligent solution like Linotouch means you’re not just buying a controller; you’re implementing a full-fledged farm management system.

Poultry farm control systems are no longer luxuries; they are vital tools in sustainable and profitable poultry production. Choose Linotouch environment controllers to ensure your broiler farm operates at peak performance—day in, day out.