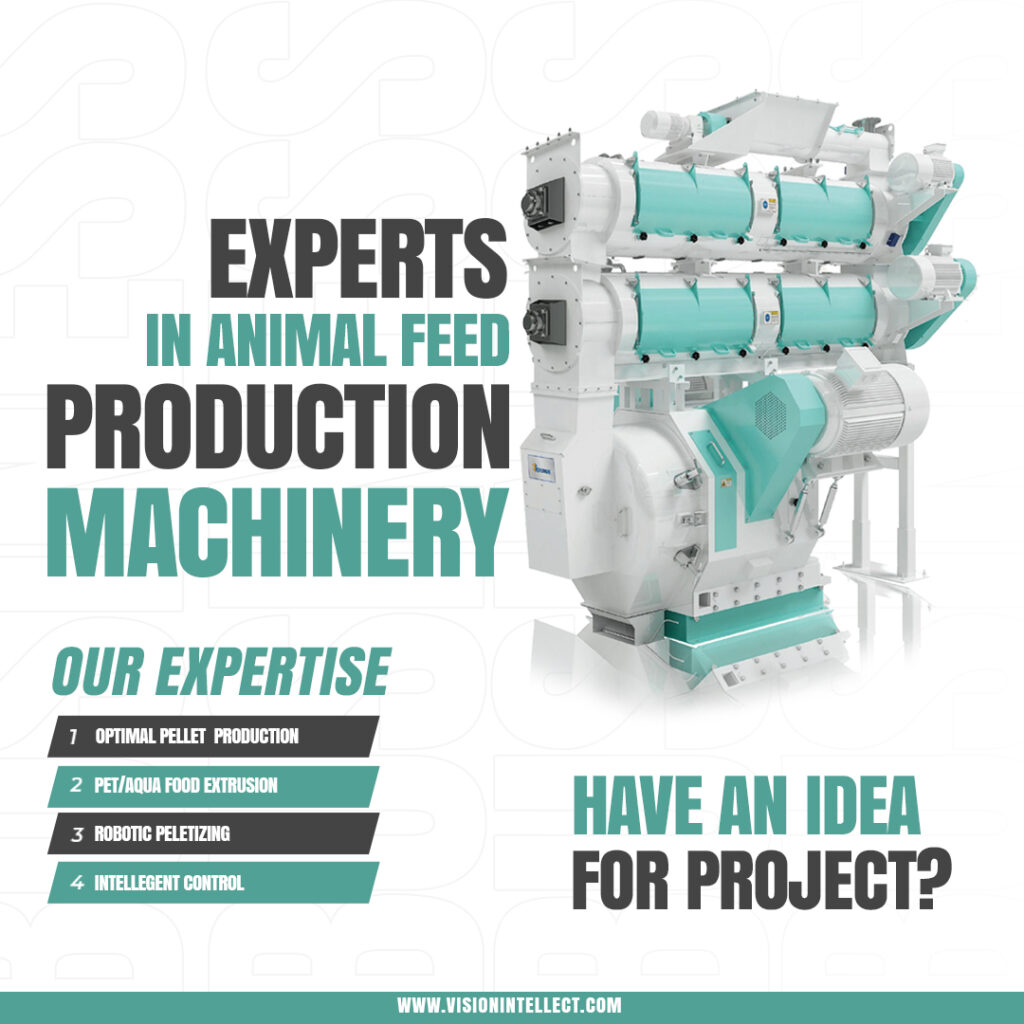

Pellet Mills and Turnkey Feed Mill Solutions for Poultry and Livestock in Pakistan

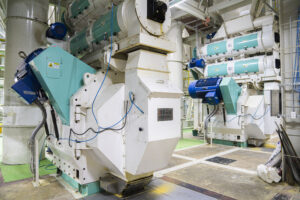

KERUNDE INTEGRATED FEED MILL SOLUTIONS

Kerunde, in partnership with Vision Intellect Enterprises, delivers complete feed mill solutions across Pakistan, catering specifically to the poultry and livestock sectors. Our systems are designed to meet the evolving demands of modern farming through innovative, efficient, and scalable technologies.

Backed by years of engineering excellence and on-ground industry experience, we provide turnkey feed mill setups that enhance productivity, reduce operational costs, and ensure consistent performance.

Our product lineup includes high-performance pellet mills, energy-efficient hammer mills, and fully automated feed processing lines. These systems are built to maintain the nutritional value of raw materials while minimizing waste.

Designed for safety and efficiency, our solutions reduce residue, prevent cross-contamination, and support superior hygiene standards. Intelligent automation and real-time process control further reduce labor dependency and improve traceability.

From raw material intake to packaging and warehousing, every component is optimized for performance, reliability, and long-term value.

Our integrated approach ensures smooth coordination between each processing stage, maximizing throughput while complying with global feed safety standards. Whether you’re upgrading an existing facility or building a new one, Kerunde and Vision Intellect Enterprises are your trusted partners for reliable, sustainable, and future-ready feed mill solutions in Pakistan.

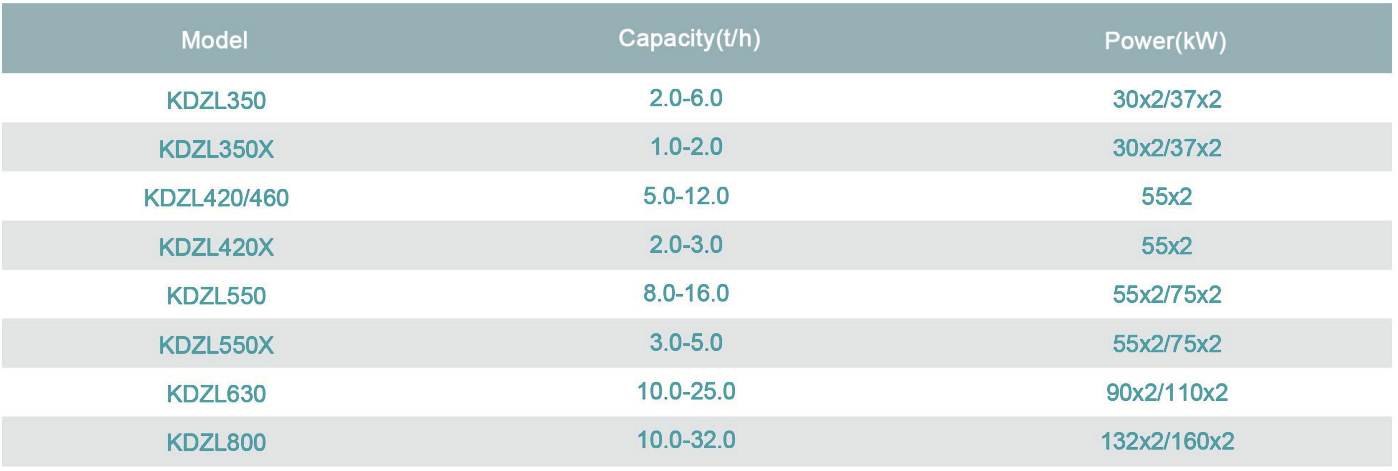

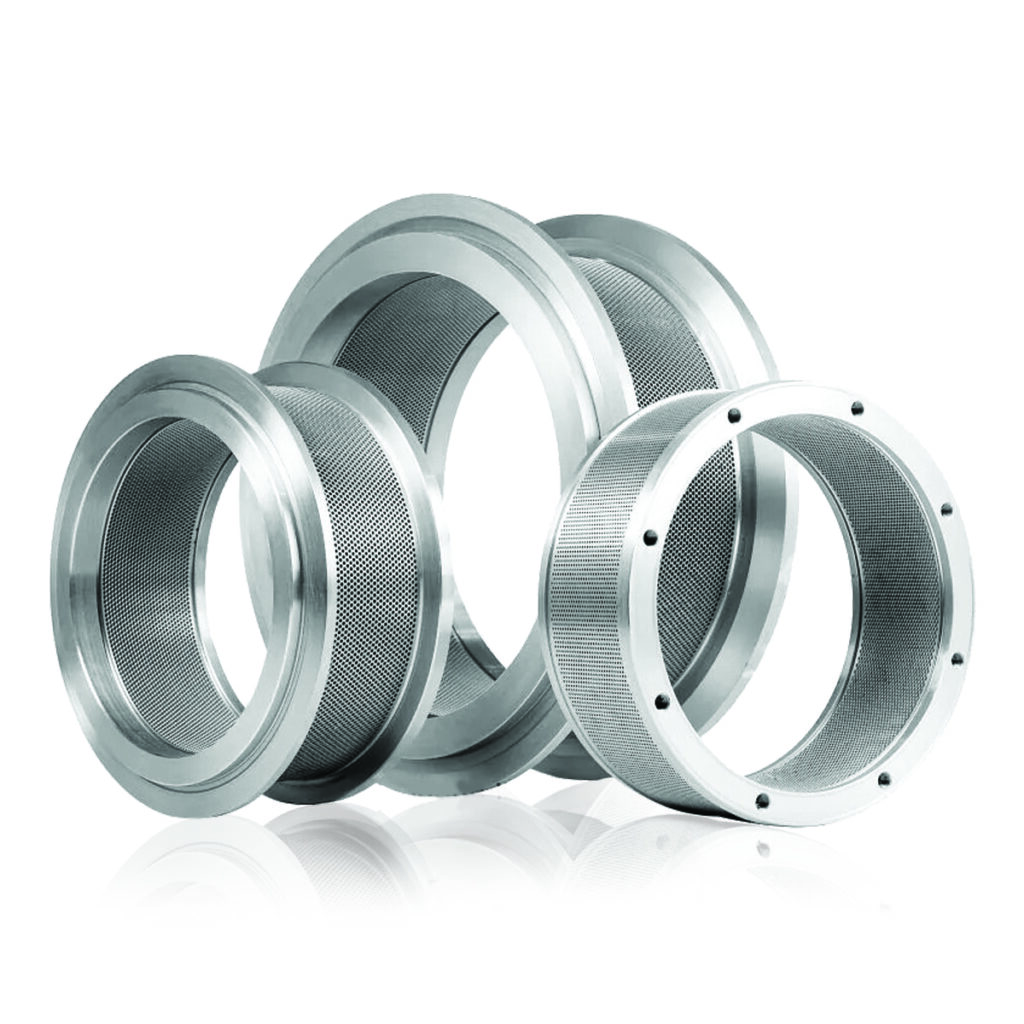

Dual Motor Pellet Mills

◆ Flexible transmission by dual-motor v-belt driving system contributes to stable running and high adaptability

◆ Excellent configuration achieves stable operation, free from worry

◆ Two rollers adopted in pelleting chamber, easy operation

◆ Adjustable angle of the cutter

◆ Optimized parameters, efficient operation

◆ Safety

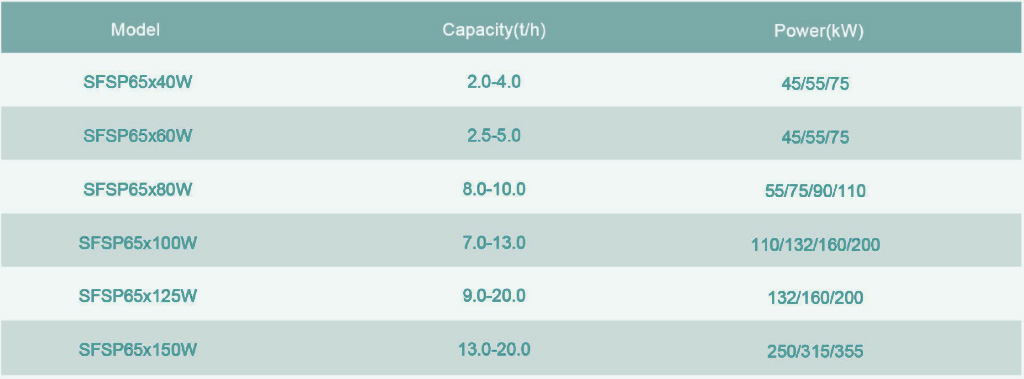

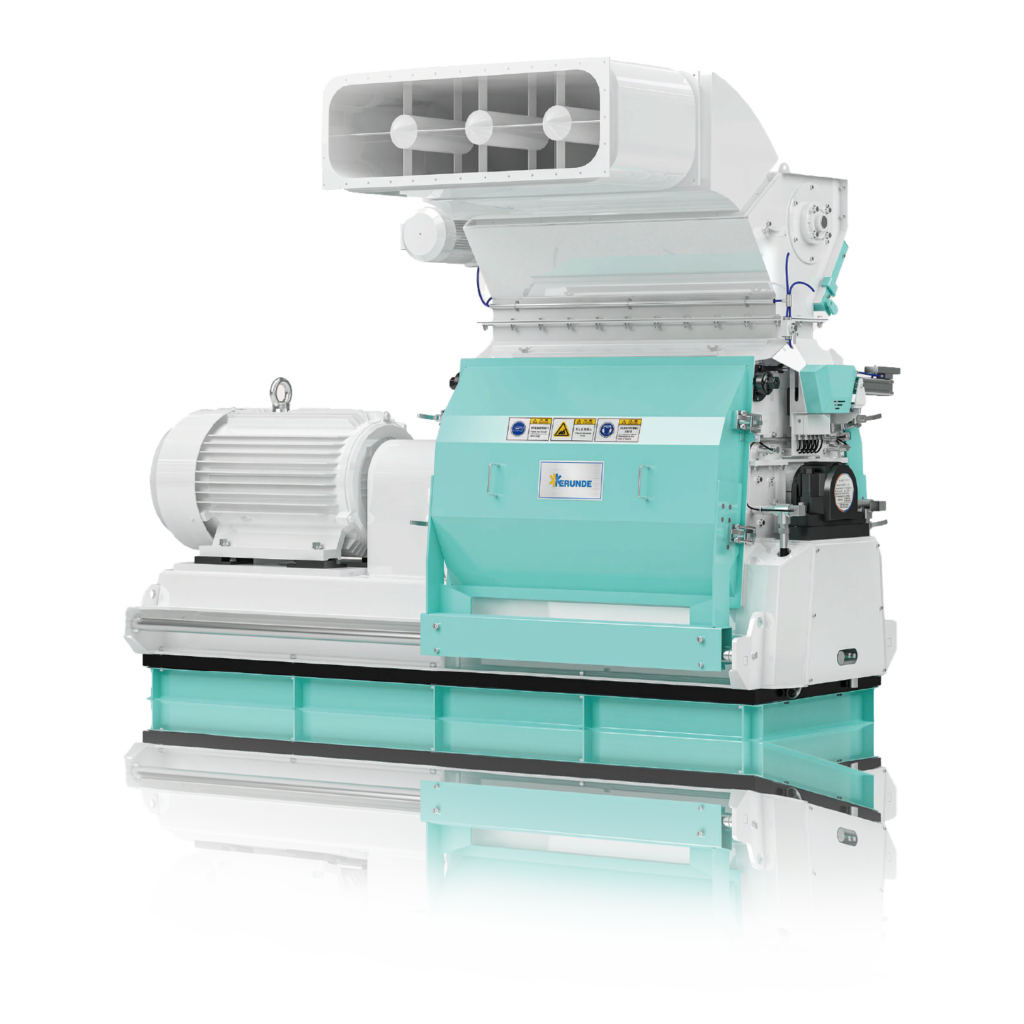

High capacity and enhanced desired grinding fineness for increased productivity and consistent output quality

Low temperature grinding helps maintain moisture content of materials, improving feed quality and nutritional value

Improved sealing performance and broader application range suitable for various materials and particle sizes

Simplified and more efficient cleaning and operation ensures user safety and reduces maintenance downtime

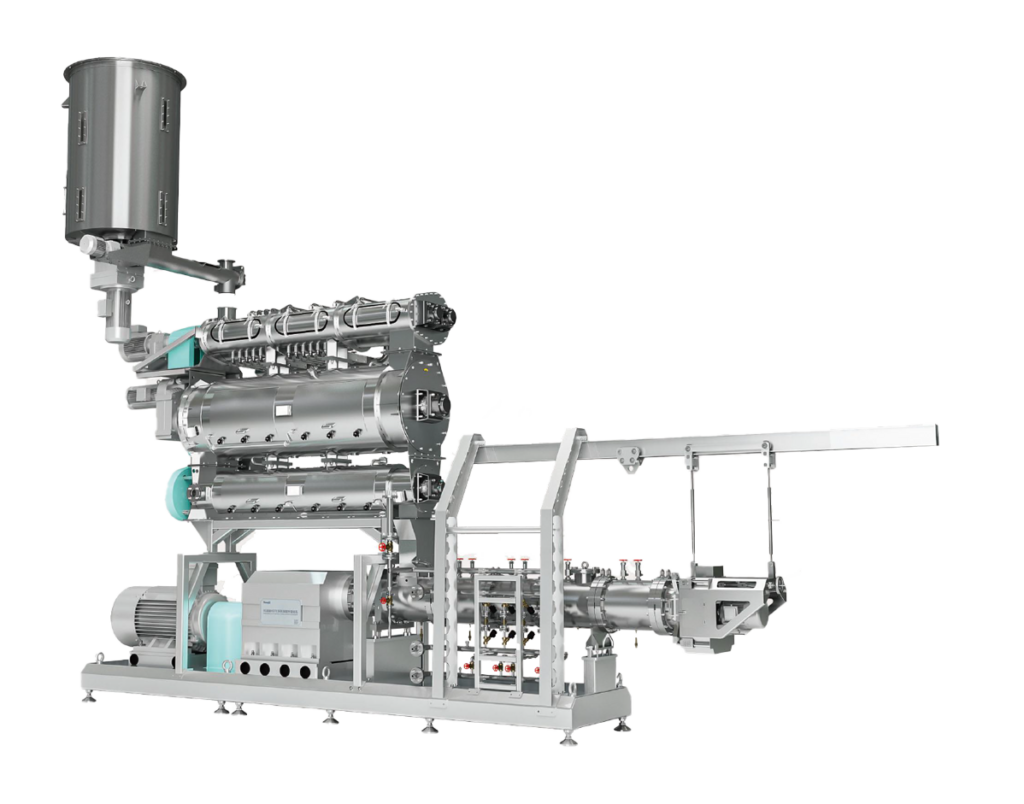

For Pet Food / Aqua Feed

- Enhanced multi-functionality of the equipment

- Distinctive uniqueness of the specialized equipment

- Superior high-quality of the finished product

- Maximized effective utilization of available energy

- Highly convenient and precise control system

- Significantly reduced minimum industrial wastewater

Twin Screw Extruder

KERUNDE provides systematic solutions for Poultry Feed, Pet Food, Robotic Palletizer and Intelligent Control

High-Efficiency Dual-Motor Pellet System with Optimized Performance and Safety

Fine Grinding Hammer Mill

Counter Air Flow Cooler

- Complete automation

- High precision.

- High efficiency.

- Better feed quality.

- Better safety.

- Simple to operate.

Pet Food / Aqua Feed Projects

Kerunde, in partnership with Vision Intellect Enterprises, offers advanced aqua and pet food production plant solutions in Pakistan, designed to meet the specific nutritional needs of aquatic species and companion animals. Our integrated farming solutions are built on years of engineering excellence and hands-on industry experience, delivering high-efficiency systems including precision pellet mills, hammer mills, and extrusion technology. These production lines ensure optimal digestibility, nutritional value, and pellet durability for a wide range of feed types.

Kerunde’s intelligent automation systems enable full traceability, consistent quality, and improved feed safety across all stages of processing. From raw material intake and grinding to mixing, extrusion, drying, cooling, coating, and packaging, every process is optimized to reduce labor costs and increase operational efficiency. Whether for floating fish feed, sinking feed, or premium pet food, Kerunde and Vision Intellect Enterprises provide complete, scalable solutions for sustainable aqua and pet feed production in Pakistan, with reliable technical support and long-term service commitments.

Our solutions are adaptable for both new setups and existing plant upgrades, with a focus on energy efficiency, reduced waste, and minimal downtime. With a customer-centric approach, we work closely with clients to ensure optimal configuration and long-term success in a competitive market.